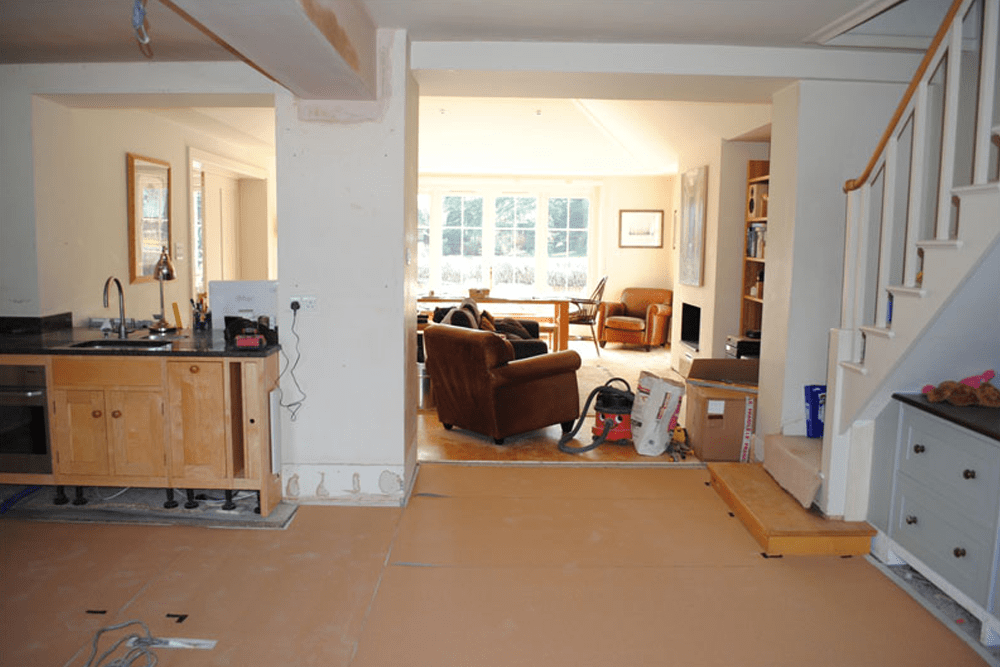

Installation of Wood Flooring

Solid wood flooring looks beautiful and once you have chosen your desired floor it is important to carefully consider the fitting process.

We can offer advice and guidelines to assist you if you are doing it yourself, but strongly recommend the use of a professional. This will ensure the flooring is laid correctly and give long-lasting performance. We have our own highly skilled carpenters ready to install your wood floor, they are very knowledgeable and work to extremely exacting standards. Please ask for full details of our floor fitting service, phone 01279 626389.

Below are some guidelines on procedures during and after installation:

Sub-floors

Site conditions

At the time of installation all building work, including wet trades, should be finished, there should be no visible or measured signs of moisture or condensation. The building should be fully glazed and heating (underfloor or otherwise) should have been commissioned (including normal ventilation) to its operating temperature for at least one month prior to the floor being fitted, but should be turned off or on very low 24 hours prior to the day of installation. Bear in mind you cannot get accurate moisture readings when under floor heating is on.

The temperature in the area to be laid should be between 18 – 22°C, and the relative humidity between 45 – 65% whilst sub-floor screeds must not exceed 75% relative humidity when measured with a surface humidity box.

Floorboard sub-floors should not exceed 10% moisture content and the sub-floor cavity should be well ventilated. If these conditions do not exist then there is no benefit in having the wood on site prior to laying.

These conditions should be maintained after installation as far as possible; a dehumidifier can be used if there are concerns about increased humidity in the building at any point after the floor is laid.

Wood floors are generally dried to 10% +/- 2% to make them as stable as possible and compatible with ‘normal’ centrally heated conditions. The wider the board the more noticeable any seasonal movement will be and it would be quite usual to expect a small gap to appear in winter when the heating is on and close up in the summer as humidity increases. Some cupping may occur on wider boards. The incidence will be reduced with engineered boards.

Exposing wooden floors to excessive humidity or temperature will cause it to distort or split, so allow the timber to adapt to its new environment slowly.

Important!

If the wood flooring needs protecting after it is laid, then the covering must be permeable to heat or the heating should be switched off thus avoiding any baking of the floor.

The area to be laid should be free of all trades and furnishing; if sanding is to be done it may be advisable to remove curtains and seal adjoining rooms.

Condition of the wood

Wood is a natural material whose colour and grain can vary; samples are only designed to give an impression of the floor and will not necessarily reflect the overall appearance of the laid floor. Any concerns about the size, colour, grade, condition or appearance of the wood should be reported to us and the boards should be not be laid without prior inspection by us. Good laid are deemed to have been accepted.

Sanding and sealing

For unfinished floors the first sanding is normally done with a large belt sander followed by a rotary sander, using progressively finer grits, for a smooth finish, so it is important that trades and people stay off the floor during this period. The floor can then be finished with either a lacquer or oil, subject to client choice.

- Lacquer – one coat of primer is usually applied and then two coats of lacquer.

- Oil – we recommend two coats of hardwax oil.

Arrangements should be made not to have anyone in the areas being sealed during this process or for 24 hours after each coat of seal is applied.

Installation dates

If a date for fitting has been agreed and the client feels this cannot be kept then we would expect at least 7 days notice notice. If we are given less than 48 hours notice we may have to levy a charge if no other work can be found at short notice. If we arrive on site and it is not ready for us to commence work, we will levy a charge of £150.00 per man per day. A new date for installation will be booked at our convenience. If it is insisted that the floor is laid then we will only proceed once written authority has been signed by the client absolving Andrew Banks Trading Limited of any responsibility should a problem occur with the floor at some point in the future. We take no responsibility for problems that may occur after our flooring is laid unless fitted by one of our approved fitting partners.

Delivery

All our hardwood flooring these days, solid or engineered, is produced in climatically controlled factories, and therefore is suitable to be laid on the day of delivery. The old adage that wood floors should be left to acclimatise in the room for around ten days prior to installation no longer applies, especially as a lot of sites have abnormal levels of moisture present beforehand and you do not want the wood to draw that in.

Goods will mostly be delivered by an independent carrier or ourselves and we would expect at least one person to be available on site to assist the driver with the off-loading and sign for goods in the case of small loads and for over 50m2 two people or a forklift.

Deposit

A non-refundable deposit is taken to confirm the order and is payable on receipt of our invoice with the balance being due on delivery of the goods or, if we are laying the floor, following completion of all works relative to the installation of the floor. In cases where a bespoke finish has been ordered we will require 100% payment with the order if we are not laying the floor and we will require and further stage payment prior to delivery.