Underfloor Heating

If you have underfloor heating and would like to enjoy the advantages of wood flooring we offer an impressive range of suitable flooring to ensure your designs are not compromised. If you have yet to decide upon an underfloor heating system we can offer advice and provide a solution suitable for your flooring and your environment. We supply the Flexel range of underfloor heating products.

The following information is intended as a guide but we would also be pleased to advise in person or on the phone.

Installation of a Floor With Underfloor Heating

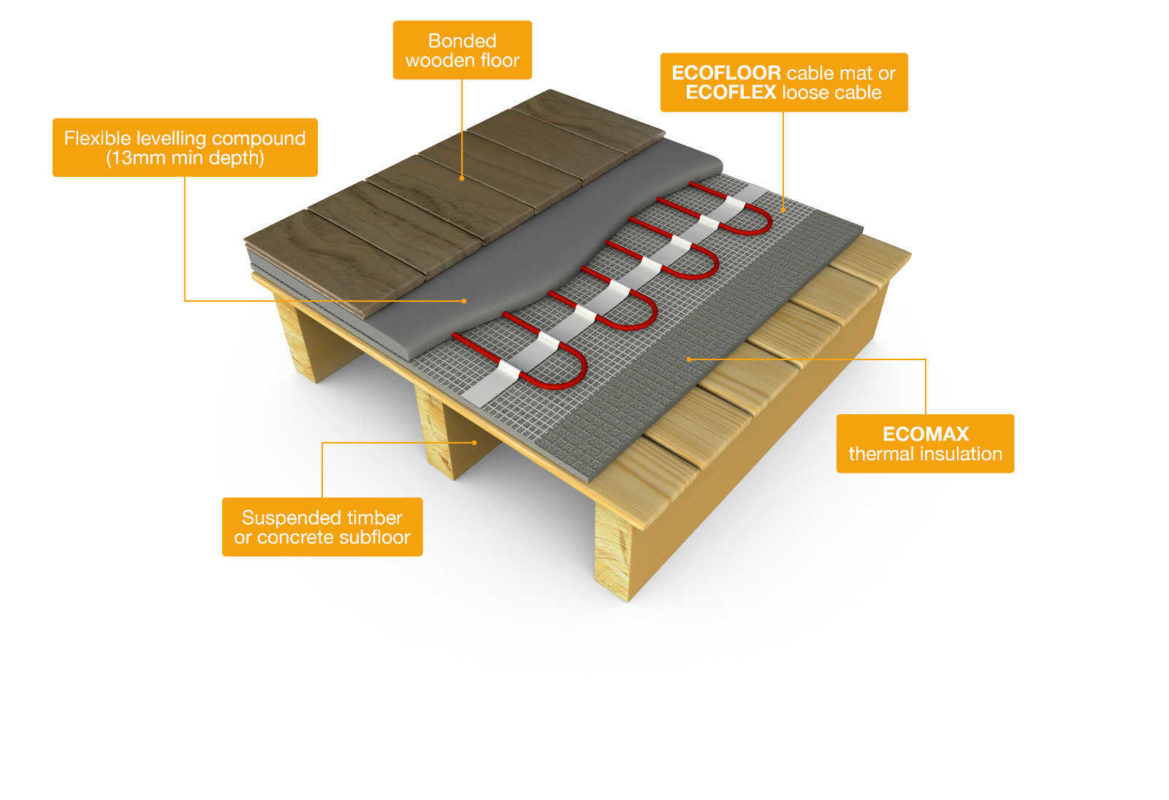

We have several floors that have been designed to be compatible with under-floor heating. The majority of these are of an engineered construction which can be floated over a suitable underlay, glued to the sub-floor or nailed to joists.

There are many different systems of under-floor heating available on the market, ranging from water fed systems set in concrete or slung between joists to electric matting laid over the sub-floor and beneath the wood floor covering.

It is imperative that the customer obtains full installation and operation instructions from the under-floor heating supplier together with guidance from them regarding the suitability of their product when laid in conjunction with wood flooring.

The most important factor when laying under-floor heating is to ensure that the pipes are set at a consistent level below the floor covering and evenly distributed to avoid heat spots. Heat spots can cause the wood flooring to move exceptionally in those isolated areas. Consequently, as suppliers and/or installers we can take no responsibility for any abnormal movement that may manifest itself at some point in the future.

Prior to installation the sub-floor should be structurally sound, clean, level, dust free and thoroughly dry.

The site should be free of all wet trades and the environment compliant with normal living conditions, i.e. humidity should be between 40 – 60% and the air temperature should not be below 15°C or exceed 26°C.

It is vital that the sub-floor is uniformly dry and that the heating is fully commissioned at least two weeks before the floor is laid. Concrete screeds take on average one day per mm of thickness to dry in a normally ventilated house but under-floor heating may accelerate this process, but care must be taken not to try and force the water out too fast as the screed can crack. It is important that the heating is started at its minimum setting and that the temperature is increased only gradually to avoid an excessive shrinkage or cracking of the sub-floor.

The use of dehumidifiers is a recommended and they are a good indicator of how the floor and atmosphere are drying out.

The heating should be increased to the maximum operational temperature (but no more than 26°C) by raising the temperature from the minimum level by a maximum of 5°C on a daily basis. The room should be well ventilated and/or a dehumidifier be put in place to allow any excess moisture to be removed.

The heating should then be run at the recommended maximum level for several days prior to installation and then leading up to installation turned off.

The sub-floor should measure a maximum of 3% moisture content by weight (concrete) or 10-12% (Timber).

The sub-floor provided should be level and this is far easier to manage at the point when the sub-floor is installed. The maximum deviation of +3/-3 over a 3m expanse of flooring is preferable. Should any filling be required at the time the wood flooring is installed, it should be noted that latex is not a levelling compound but can be used to make the surface smooth and free of humps.

The wood can be delivered to site 2 or 3 days prior to installation to allow some acclimatisation, but it is not essential, provided all the above circumstances are in place. You should avoid exposing the wood to excess humidity. The heating system should not be in operation during installation.

Floating installation

When floating the floor, we recommend using a 2mm poly foam underlay or a similarly permeable membrane, which allows the heat to be transferred to the wood without hindrance whilst also providing an element of sound-proofing. Use D3 PVA adhesive with a tongue and groove board or use a board with a recognised brand of “clic” or “lock” dry fix profile. We supply the Flexel range of electrical under floor heating products please ask for details.

Installation on the sub-floor by gluing

We recommend that the gluing should be done by a professional installer.

The boards should be fully glued to the sub-floor using a suitable flexible adhesive with a maximum application of 1.2kg per m2. This ensures an efficient transfer of heat and reduces the risk of hot/cold pockets and bouncing that can be a risk with a floating floor.

Place weights on the floor or pin the boards down where appropriate whilst the glue dries.

Pay particular attention to heavy traffic areas.

After the installation

The under floor heating should be off during installation.

Raise the temperature slowly from its minimum setting to a maximum of 26 degrees centigrade, evenly over a period of at least one week. Then reduce the temperature slowly, by similar increments of about 5 degrees every 24 hours, to a comfortable living temperature. Do not exceed 26 degrees during normal operation.

Important!

If the wood flooring needs protecting after it is laid, then the covering must be permeable to heat or the heating should be switched off thus avoiding any baking of the floor.

One should also expect some seasonal movement in the wooden floor, which may lead to gaps appearing between boards when the heating is at its winter setting which should then reduce in size in the summer months when the heating is off or low and humidity is increased. For this reason we recommend using a bevel edged engineered board to help disguise any seasonal movement.

The ambient air humidity must be kept at between 40 – 60%. Recommended room temperature is 18 to 24 degrees centigrade. If these conditions are not observed, abnormal movement may occur. The manufacturer, seller or installer cannot accept any responsibility for such occurrences.

If there are any doubts or you have further questions, please contact your under-floor heating supplier and your wood flooring installer, as the manufacturer of the wood flooring cannot be held responsible for any problems that may occur due to bad site practice.

If you would like to talk to us about how we might be able to help you please call us on 01279 626389.